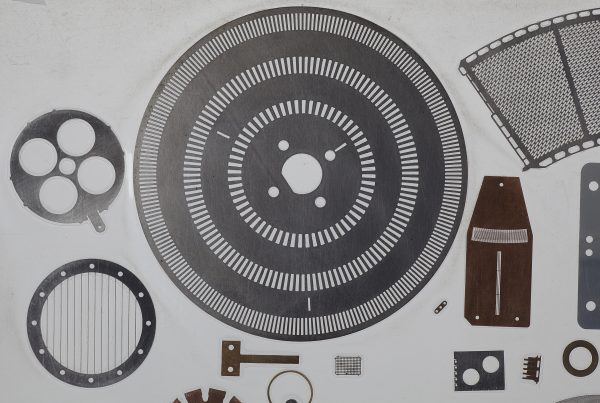

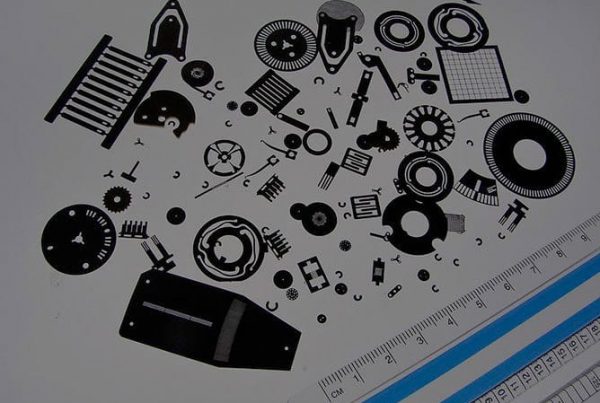

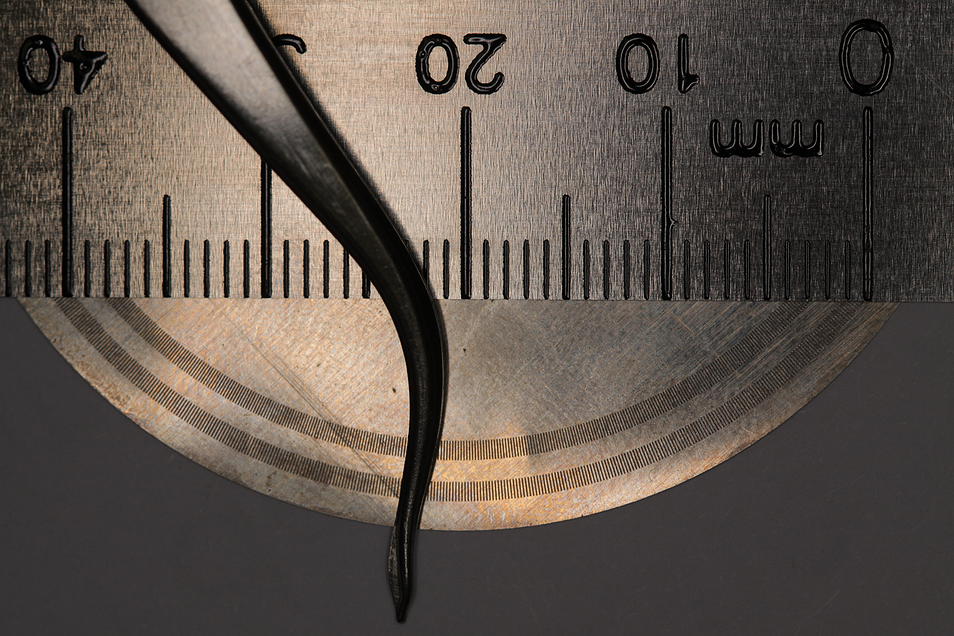

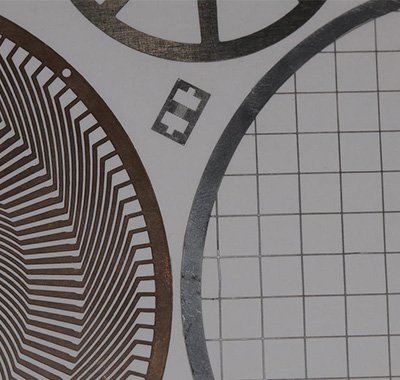

With 30 years of experience in precision metal fabrication,precision photo etching and electro-forming and has served over 20 different sectors and industries such as Automotive, Aerospace, Medical instrumentation, Microelectronics. Shimifrez has helped many projects move from R&D into Production. The same tooling and process is used for prototype and production parts, so development work is relevant and reliable.

We would like to introduce Shimifrez as a micro manufacturer/fabricator of parts and consumable components for all makes and models of Chemical Etching/Photo Fabrication.

”Shimifrez is committed to a culture of continuous improvement.

Hassan NojoumiPresident of Shimifrez Inc